Cooperative Offers

* For a short period of time

* Annual turnover – potential over 250 000€

* With minimal expenses – 1sq.m. of trade corner

* 1 million proposals – models, sizes, fabrics, accessories and price groups

* Without investments in stock

* Without risks of unsold products

* Without missed sales

* Easy expansion of your business all over the world – potential annual turnover over 1 million € with minimum investments for a new trade corner

Take your business to the next level

Overpass your competitors

Create your own world brand and significantly increase its value

Cantarelli is looking for partners and agents worldwide

Why today is a big opportunity to start a business with Made to measure suits?

The new challenges in the fashion business:

Significant reduction of the demand from end customers – 50 – 70%

Many unsold products from previous seasons

New world brands positioning on local markets

Strong competition from online shops

Increase in the number of outlet centers

https://cantarellituscanlifestyle.eu/

How do we achieve the new business model?

By successful implementation of the principles of the automotive industry in the fashion industry and the change of the whole supply chain from fabric production and clothing manufacturing to marketing and final sales at the shops, Cantarelli achieved unique results:

Price - Luxury at an affordable price

Made to Measure suits at the price of Ready to Wear

End price for the customer - 250€ - 450€ - two times lower than the standard price of Made to Measure.

Quality

maintaining high production quality through the use of Italian know-how in the technology of manufacturing and German precision through large investments in the most modern machines in the industry.

Fabrics

all garments are made with CANTARELLI SELECTION FABRICS, MADE IN ITALY.

Production lead time

express lead time – 7 – 10 working days.

- significantly shorter than the current one for MTM garments.

Easy system for training the new staff

We offer FREE online training on taking measurements which takes only several hours.

The staff doesn’t need to have many years of experience.

Fashion consultants can be easily found for the expansion of the business.

1sq.m. trade corner = over 1 000 000 proposals

For the MTM business model is needed only 1sq.m of trade corner, where to be put suit samples, fitting suits, and fabric catalogs.

The trade corner is made on the principle of the automotive showrooms. Sample cars and catalogs offer huge possibilities to create an individual product for the customer.

Through the MTM trade corner can be offered over 1 000 000 combinations of sizes, models, fabrics, linings, and accessories from different price groups.

With this huge variety, all target groups and customer wishes are covered – from 100 potential buyers, 90 would purchase.

Standard Ready to wear shops keeps large trade spaces and warehouses.

RTW can’t offer the variety, which an MTM trade corner can – from 100 potential buyers, 90 are lost.

How to start the Made to measure business model?

Get in touch with us now: Email: ceo@cantarellituscanlifestyle.it Tel: 0039 338 433 2367

The MTM trade corner requires only 30 fitting suits for taking measurements. Special offer of the fitting suits made with natural wool fabric x70€ (production price).

We will provide you with material catalogs free of charge as well as "Cantarelli Selection Fabrics".

Cantarelli gives new fabric selections several times per year in order for you to be able to advertise new products in front of your potential customers all the time.

We will provide FREE online training on taking measurements which takes only several hours. Every average shop assistant can learn the system easily.

We will make a special online consultation for the business development and marketing strategy.

All orders are placed on our website: www.cantarellituscanlifestyle.it. We will assist you with placing orders.

You can start working with the business model right away.

You can return your investment for the fitting suits in the first month.

The MTM business model allows starting the business, without having experience as a fashion consultant.

Cantarelli is looking for partners all over the world.

Cantarelli innovative production line for Made to Measure suits on the price of Ready to Wear

Successful implementation of the principles of the automotive production line in the fashion industry

*European funding of the production line aiming for the preservation and development of new working places in Europe.

*Annual capacity of the production line – 250 000 garments

*Production lead time – express 7 – 10 working days lead time without additional surcharges.

*Italian traditions – Cantarelli uses its Know-How in developing the new production line.

*Design of the collections – 12 collections per year. The design of the garment collections and fabric selections is developed by Tuscan designers with 30 years of experience in developing collections for luxury brands.

*Production technology – Half Canvas, Full Canvas, Deconstructed, Fused

*German precision – use of the most modern German machinery – Durkopp, Veit, Pfaff, Strobel, Brisay.

*CAD-CAM – Lectra, France – software for developing single patterns and 25 cutting robots.

*Production transport – Eton system, Sweden.

*100% European production – the European certificate for all used materials in the manufacturing of the suit.

*Due to all benefits of the production line, the high production quality is achieved.

*Selection fabrics – Cantarelli invests in creating CANTARELLI SELECTION FABRICS AND LININGS, MADE IN ITALY. Over 5000 fabric articles and over 1000 lining articles on stock.

*Price of the products – Cantarelli’s innovative production line achieves high productivity and significantly reduces the costs through automation.

*Price – Luxury at an affordable price Made to measure suits at the price of Ready to wear. End price for the customer – 250€ - 450€ - 2 times lower than the current selling price for Made to measure.

The result – Luxury at an affordable price – Made to measure suits at the price of Ready to wear.

A huge market niche is found for Made to measure suits on the place of production and sales of Ready to wear garments.

Your brand will receive significant marketing support from Cantarelli

Together with the Italian company Cantarelli you can achieve quick and significant results through the development of your business strategy and strong marketing support.

How to develop your brand quickly

How to open your own or franchise shops worldwide

Presentation of your brand at Cantarelli Fashion Week in Italy and in 10 more world fashion capitals

12 fabric selections annually

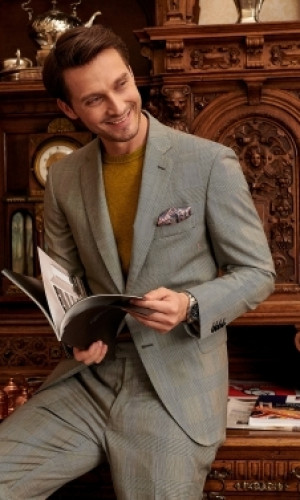

Advertising materials - unique instruments for sales: videos, photoshoots, catalogs

Become a partner or an agent of Cantarelli

NACE Codes

- C.14.19 - Manufacture of other wearing apparel and accessories

Economic Sector: COMMERCE AND DISTRIBUTION

Offer Type: Representation